Click image to enlarge

Quick Links

Neodymium Magnet Material - Powerful & Cost Effective

Neodymium Iron Boron (NdFeB) magnets were commercially introduced in the early 1980s, and are widely used today for many different applications. The cost of neodymium magnet material (on a dollar per energy product basis) is comparable to that of ferrite magnets. *NdFeB magnets are covered by various patents and only licensed materials are allowed into the USA.Integrated Magnetics designs and builds custom neodymium magnets and magnetic assemblies, manufactured to meet your specialty requirements. Send us a request for quote or contact us today for more information about standard or custom neo magnets. Large inventory of neodymium magnets are also available for on-line purchase at MagnetShop.com.

Key Benefits of Neodymium Magnet Material

- Very high strength.

- Relatively low cost: by weight, about 20x Ferrite magnets, by "Dollar per BHmax" about 1.5x ferrite magnets.

- Relatively easy to machine, compared to alnico and samarium cobalt magnets.

Key Challenges of Neodymium Magnet Material

- Properties deteriorate rapidly at temperatures in excess of about 150°C depending on grade and permeance coefficient at which the magnet operates at.

- Most grades of NdFeB magnets need to be protected against oxidation by coating or plating the magnets.

Quick Facts about Neodymium Magnet Material

- Density: 0.275 lbs. per cubic inch.

- Saturation magnetizing field required: about 35kOe.

- Manufacturing methods - sintering (most common), injection molding, compression bonding, or calendaring.

- Available shapes blocks, bars, discs, rings, arc segments, etc.

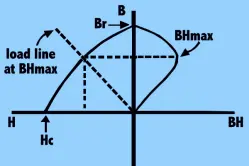

- Available grades: from about 3330 to 5311. (First 2 digits represent BHmax; second two digits represent intrinsic coercivity, or Hci.)

- Sizes: Off tool, the largest die pressed blocks are about 4" x 4", while isostatically pressed blocks can be much longer in the orientation direction (up to 9').

- Machining: Neodymium magnets should be machined by grinding, using diamond wheels. Of the hard magnet materials, Neo magnets are the easiest to machine. We have successfully machined very small magnets-down to 0.012" diameter with a center hole of 0.003" diameter, and a length of 0.040".

Surface Treatments for Neodymium Magnet Material

- Painting, coating, or plating is generally recommended for NdFeB, although recently certain grades have been made that exhibit higher resistance to oxidation.

- Plating NdFeB is a difficult process, and commercial plating houses unfamiliar with the specialized plating techniques required are unlikely to be able to achieve plating with good adhesion on Neo magnets.

- Nickel, zinc, or tin plating provides good corrosion resistance for NdFeB magnets, though longer lead times or higher volumes may be required for these. Neo magnets can also be plated using ion vacuum deposition (IVD) techniques. This specialty plating is very controllable for thickness and has excellent adhesion to the material.

- A variety of organic coatings have also been successfully developed for NdFeB, exhibiting good corrosion resistance characteristics. For especially harsh environments, it may be advisable to use a combination of coating techniques, or to encapsulate the material in a sealed housing.

- NdFeB powder is very fine and when dry can ignite spontaneously; special care must be taken when handling NdFeB powder.

- NdFeB magnets are very powerful; special care must be taken in handling these magnets to avoid injuries.

- NdFeB magnets are susceptible to corrosion.