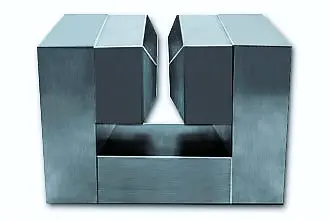

Permanent Magnet Dipoles & High-Field Magnetic Yokes

Permanent Magnet Dipoles are used to create powerful and highly uniform magnetic fields in the gap between the magnetic poles. They are built with strong permanent magnets in conjunction with a steel yoke (return path), which is an integral part of the magnetic circuit design.

Applications

Magnetic Dipoles and yokes are used for applications where powerful and/or high-uniformly magnetic fields are required. Applications include portable nuclear magnetic resonance (MR & MRI) equipment, magnetic yokes created for nano particle separation, magnetic annealing, probe calibration, magnetic mass spectrometer applications & more.

Design & Manufacturing Capabilities

- We are able to design dipoles to your specifications, using Finite Element Analysis tools, and produce magnetic dipoles in prototype or low to medium volume production quantities as needed.

- Our In-house manufacturing capabilities include CNC machining of metal components, EDM, magnet grinding, assembly (including cleanroom assembly), coil winding, flux testing, magnetic characterization, serialization, and fully equipped metrology labs.

Specialty Halbach Array Magnetic Assemblies

In addition to magnetic dipoles, we are experienced in producing special, custom Halbach array magnetic assemblies, such as quadrupoles, sextupoles, and other open magnetic assemblies with focused fields, and sinusoidally varying magnetic fields. Applications include robotic surgery, ion beam manipulation, etc.

Testing & Inspection Capabilities

ISO 9001:2015 certified, registered at DDTC and ITAR compliant, Integrated Magnetics has a well-established QMS and proven testing methods to ensure zero-defect components. We utilize state-of-the-art technology to ensure that all our magnets and magnet assemblies adhere to all applicable industry and/or customer standards and meet or exceed customer expectations. Our inspection equipment and testing methods include:

- State of the art inspection equipment

- Vision & gauging systems

- Flux checks with multiple defined points

- 3-D magnetic field mapping

- Environmental testing: hot, cold, salt, fog, shock, vibration, etc.

- Statistical process control, analysis tools & more

Additional test processes are available upon request to meet your unique requirements.

Your Custom Magnetic Assembly Project, How Can We Help?

Working with an experienced magnet engineering and manufacturing team is essential for successfully producing complex magnetic assemblies. Contact us today or send us a Request for Quote about your specialty project and let us know how we can help.

Request A Quote Contact Us